A "feature" of the SWTPC was the perforated metal cover with aluminum trim. You had the remove 14 screws to get the cover off. People ran the computer with the lid off or just placed on the case. Often when the SWTPC 6800 comes up for auction on eBay it is missing the aluminum trim.

The aluminum trim is easy to replace. You can get the 1/16 inch thick 3/4 inch x 1/2 inch unequal angle at a hardware store. It cost around 3 or 4 dollars for a 36 inch length. The screw are 6-32 3/8 inch truss head screws. I found them in a specialty fastener store.

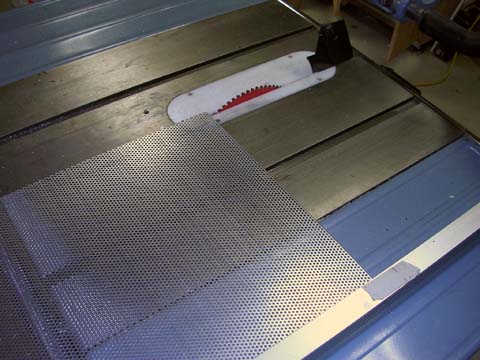

I received a SWTPC 6800 without the cover and wondered what to do with it. Earlier I had determined what type a aluminum was used for the cover. I had been thinking a modifying a new PC case to look like a SWTPC so I ordered a sheet of perforated aluminum. The material is 1/8 inch round hole, 3/16 inch center, 60 degree angle, 0.063 inch thick 3003H14 perforated aluminum. I got a 36 by 96 inch sheet from McNichols Co. for $120. That is enough for 6 cases, but they do sell smaller amounts. (This is not going to be a cheap project.)

Sheet aluminum is easy to work with just a few special tools. I cut the metal on my table saw. If you are going to make just a few cuts you can use a normal carbide woodworking blade. However these blades are more likely to bind then kick back the material. I bought a Freud model D1080N non ferrous metal saw blade for around $55. This blade is also good on plastics.

To bend sheet metal you need a tool called a bending brake. The case is a bit over 15 inches deep so that rules out 12 inch brakes. They make some light weight brakes for $20 but they only handle thin material. Bending brakes tend to be rated for a gauge of steel as 22 gauge or 18 gauge. There is no standard method of converting gauge to a thickness. Also you can bend aluminum that is about twice as thick as steel. Anyway I have a 24 inch bending brake rated for 18 gauge steel (Grizzly Model H2788.) I clamp it to my table saw to use it.

Here is the resulting cover before paint. Applying paint to aluminum is easy, getting the paint to stick is very difficult. The paint on my 25 year old SWTPC cases is still in good shape. There is a metal finishing place around the corner from my work so I will probably get it painted there. I will get several done at the same time.

I have been thinking about how to do a Case Mod so a modern case will look like a SWTPC 6800. I have found a case that is almost the same size, the In Win D500. I will replace the lid with perforated aluminum and make a new front panel from black acrylic plastic. I will use big red and white switches for power and reset.

Here is the new cover. The front panel will be black acrylic plastic. I am going to send this cover (and other stuff) out for painting. The lower panel still needs to have the holes for the power switches. The SWTPC logo will be applied with a water slide decal made with a laser printer.

I got the case painted and have started to assemble it. I have enough materials to make a second case which I will sell.

Here is the assembled unit. The mother board is an ASUS P4P800VM with an Intel 865G chip set. The board has a 3 GHz Pentium 4 with 512 MB of RAM. The Sony DRU- 720 is a double layer DVD burner (8.5 GB DVDs). The photo above shows the memory card reader. (I will do the floppy drives in an external case.)

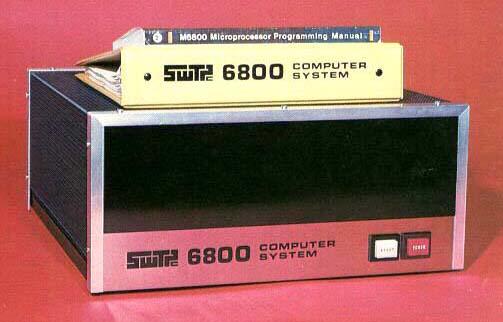

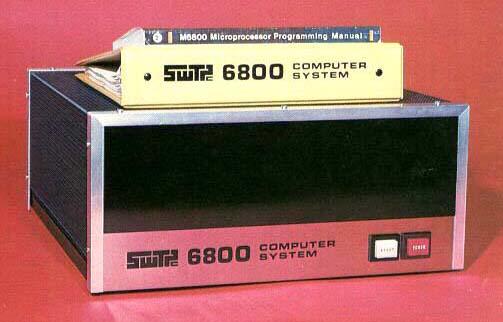

Here is an original SWTPC 6800 Computer.