| .Many a would-be writer dreams of free-lancing his way to a fortune,

but few would-be business owners consider freelance writing as a means

to their end.

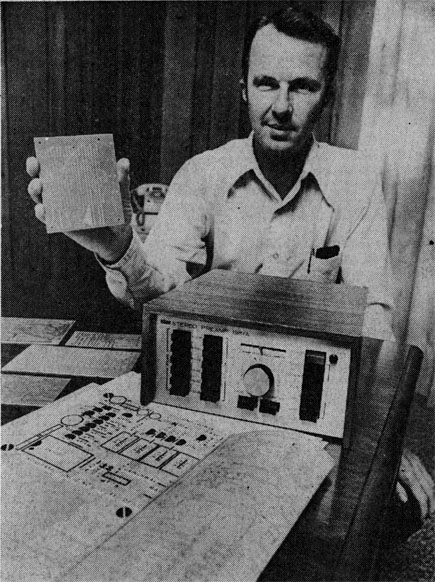

Daniel Meyer did. Owner of Southwest Technical Products Corp., Meyer

built his mail-order business from scratch to more than $1 million in

sales in six years.

Born in New Braunfels and raised in San Marcos, where he earned a

bachelor's degree in mathematics and physics from Southwest Texas State

University, Meyer worked for six years for Southwest Research Institute

in the electrical engineering department.

Meyer says he wrote a few articles for Popular Electronics and Radio

Electronics magazines on items such as amplifiers and "electronic

gadgets". The article would wind up by noting that some parts needed to

put together the gadgets were available from Meyer.

"When I realized how many people would pay me a couple of dollars for

a circuit board, I figured they'd also pay a little more for a whole kit

to make something," Meyer recalls.

"Luckily I was right. I started this business in 1964. For the first

five or six years we didn't have to advertise a bit. No one had ever

done what I did before, but it worked," Meyer adds.

Meyer wrote an average of four articles per year for either of the

two widely circulated electronics magazines. Most of the articles were

accompanied by a picture on the cover of the magazine.

This arrangement developed as a double source of income-Meyer was

paid for writing the article, which in turn generated sales for his

budding company.

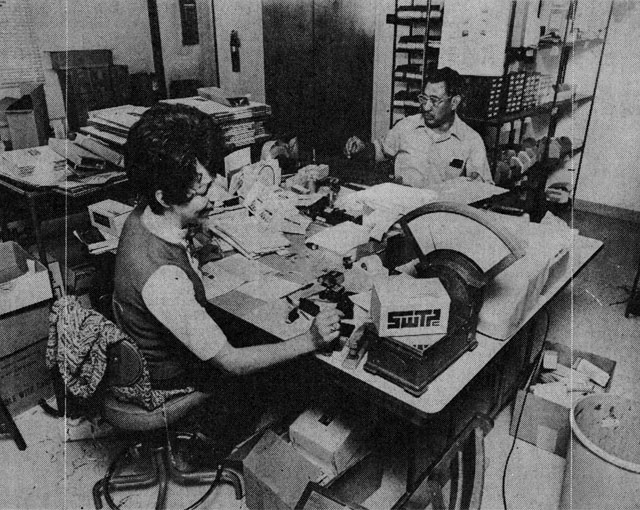

The business quickly outgrew the Meyer garage and is presently

located in 18,000 square feet of buildings on three acres at 219 W.

Rhapsody St.

"Our sales were doubling every year and we'd run out of space every

time we'd get some new machines in," recalls Meyer. "We've built out

here about four times now".

"Every time we put up a new building we say, 'God, there's all kinds

of room,' but it sort of fades away. Things are filling up again now,"

he adds.

Meyer counts his business as fortunate in several respects. He could

build as his sales increased, for example, and add employees only as

necessary.

A market already existed for Southwest Technical Products, and Meyer

could usually offer his items at lower cost than competitors' items were

offered at retail counters in stores.

"This business has also been fortunate in that we get the money in

our hot little hands before we send out the product. We don't have to

worry about depending on one or a few large customers who might go broke

or be slow paying," says Meyer.

Meyer adds that the recession of 1970 didn't hurt his company too

much. "Instead of sales increasing more than 20 per cent, that year they

only increased about three per cent-which was nice, it gave us a little

breather," he says.

The office staff sends out thousands of catalogs each year and Meyer

says the company also has begun to advertise, though he still writes an

occasional article for the popular magazines.

Letters and orders come in at the rate of more than 100 per day, and

an average of 100 kits are shipped out daily, Meyer says. Though the

company lets all checks clear their respective banks before filling the

orders, Meyer says bad checks represent only a tenth of one per cent of

sales.

"More than 50 per cent of our market seems to be made up of young

people high school and college age-who enjoy working on the kits we

offer. They want the stuff, and they aren't about to take a chance of

not getting it by sending a bum check," Meyer theorizes.

The language in the company's catalog is written to appeal to this

youth market. The most recent issue notes that customers have written

expressing doubts about the company's products because the prices are

low.

"The truth is that we are setting our prices at a fair level for our

way of selling these kits to you," states the catalog. "Since you are

buying by mail directly from the manufacturer you are saving at least

one third since there is no retailer's markup."

"If you don't believe this, compare our kits with others on the

market. This should make it obvious who the rip-off is," concludes the

catalog.

Another section assures customers that "no surplus, no rejects, or

reduced specification garbage is ever used in a SwTPC kit."

This approach sells a lot of product. Meyer says sales have topped $1

million for the past two years and are running well this year.

Two items in the catalog carry the name of Popular Electronics

magazine on them, but the majority carry the company's SwTPC initials.

In addition to preamps and amplifiers the company offers guitar

amplifiers, psychedelic strobe lights, electronic musical instruments,

and color organs which shine flowers of various colors on a glass screen

according to the pitch of the music connected to the organ.

Such currently popular items as burglar alarm systems and battery

chargers are also offered. The current catalog also offers a product

Southwest Technical Products pioneered, a digital car tachometer which

indicates revolutions per minute of a six-cylinder or eight-cylinder

engine in lighted digits rather than a needle on a dial.

"We aren't getting in too many orders for it yet," says Meyer, "but

it's still new and we still think it's a good product. You win some and

you lose some, but as long as you don't lose too often you're all

right."

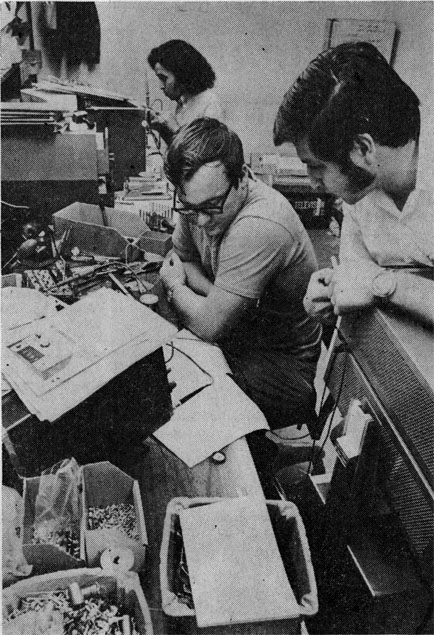

Meyer says research and development don't cost the firm too much

because it already makes its own circuit boards, and most of the

electronic parts are usable in several items already in the product

line.

"We also have a real good time at what we're doing," Meyer asserts.

"We were really interested in seeing what type of circuit that digital

tachometer would need."

The company adds an average of six to eight new products to the line

each year. One that bombed a while ago was an electronic dice game.

"We had it wired and programmed to give the same odds as throwing the

cubes," says Meyer. "All you had to do was press a button and the lights

on two panels would show what you 'threw.' We figured anyone liking to

gamble would have to have one, but it was a total disaster."

Meyer says that in retrospect it seems gamblers and casual dice

players enjoy the feel of the ivory in their fists, the clicking sound

as they shake the cubes, and the physical action of throwing dice.

Demand remains strong for the other kit items in the company's line,

however, and Meyer says he may move into another market.

"We know there are more people who'll buy assembled products than the

kits that we sell now. We'll move into that area as we can handle it,"

he says.

|